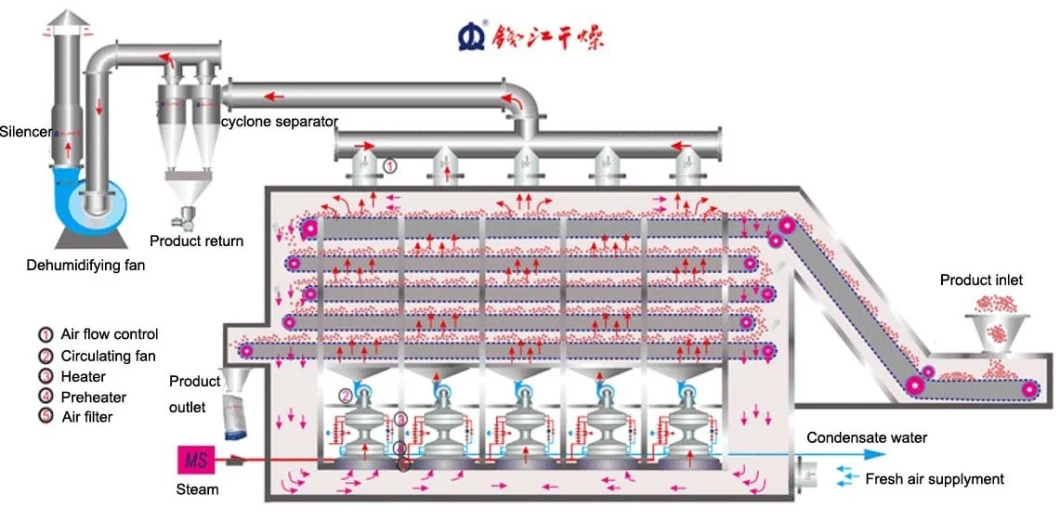

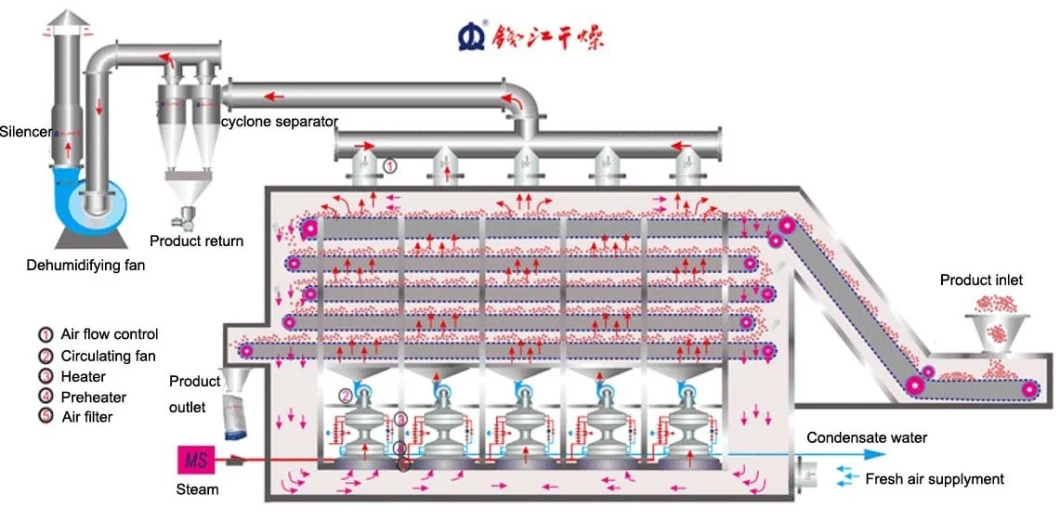

Working Principle:

It is a continuous belt drying machine for batch production. This series of dryer features high drying speed, strong evaporation intensity, and good quality. For the paste-like materials such as dehydrated filter cake, they can be dried after being granulated or shaped into strip.

Product Features:

DW series multi-layer belt dryer is suitable for large-scale production of difficult-to-dry materials with low drying rate. The equipment has compact structure, small footprint, simple operation, convenient maintenance and stable operation. It can be designed into different hot air circulation drying forms according to the drying characteristics of the materials. It is an extension and improvement of the hot air circulation oven. With the technological advancement of the enterprise and the improvement of the technical content of the products, the multi-layer belt dryer has the ability to meet large-scale production, diversification, centralized control and continuous production. It has the advantages of high efficiency, energy saving and easy management.

Application:

It is used for drying sheets, strips and granules shaped materials with good air permeability. It is widely used in metallurgical additives, chemical industry, food, packaging and other fields, especially suitable for materials with high moisture content but the material temperature is not allowed to be high, such as coconut chips, dehydrated vegetables, catalysts, pharmaceutical herbal medicines, food, vegetable, fruit, tea, cassava chips, cocoa beans etc.

Technological Process:

Technical Parameters:

Table1. Basic parameters of DW series nine-layer dryer

Table2. Basic parameters of DW series seven-layer dryer

Table3. Basic parameters of DW series five-layer dryer

Table4. Basic parameters of DW series three-layer dryer

It is a continuous belt drying machine for batch production. This series of dryer features high drying speed, strong evaporation intensity, and good quality. For the paste-like materials such as dehydrated filter cake, they can be dried after being granulated or shaped into strip.

Product Features:

DW series multi-layer belt dryer is suitable for large-scale production of difficult-to-dry materials with low drying rate. The equipment has compact structure, small footprint, simple operation, convenient maintenance and stable operation. It can be designed into different hot air circulation drying forms according to the drying characteristics of the materials. It is an extension and improvement of the hot air circulation oven. With the technological advancement of the enterprise and the improvement of the technical content of the products, the multi-layer belt dryer has the ability to meet large-scale production, diversification, centralized control and continuous production. It has the advantages of high efficiency, energy saving and easy management.

Application:

It is used for drying sheets, strips and granules shaped materials with good air permeability. It is widely used in metallurgical additives, chemical industry, food, packaging and other fields, especially suitable for materials with high moisture content but the material temperature is not allowed to be high, such as coconut chips, dehydrated vegetables, catalysts, pharmaceutical herbal medicines, food, vegetable, fruit, tea, cassava chips, cocoa beans etc.

Technological Process:

Technical Parameters:

Table1. Basic parameters of DW series nine-layer dryer

| Model | Unit | DW9-1.2-6.4 | DW9-1.2-8 | DW9-1.6-10 | DW9-1.6-12 | DW9-2-16 | DW9-2-20 |

| Mesh width | m | 1.2 | 1.6 | 2 | |||

| Drying section length | m | 6.4 | 8 | 12 | 16 | 20 | 24 |

| Material distribution thickness | mm | 30~50 | |||||

| Operating temperature | ºC | 50~80 | |||||

| Steam pressure | mPa | 0.2-0.5 | |||||

| Water evaporation | kg/h | 150~260 | 180~315 | 290~500 | 350~610 | 570~1000 | 720~1250 |

| Steam consumption | ≤2kg steam/Evaporation 1Kg water(for vegetable&Chinese herbal medicine) | ||||||

| Total power | kw | 33 | 42 | 70.5 | 84.5 | 142 | 176 |

| Dimension(l×b×h) | m | 9.5×1.8×5.7 | 11×1.8×5.7 | 13×2.2×5.7 | 15×2.2×5.7 | 19×2.6×5.7 | 23×2.6×5.7 |

| Weight | kg | 13000 | 16500 | 27350 | 32800 | 54800 | 68500 |

Table2. Basic parameters of DW series seven-layer dryer

| Model | Unit | DW7-1.2-8 | DW7-1.2-10 | DW7-1.6-8 | DW7-1.6-10 | DW7-2-8 | DW7-2-10 |

| Mesh width | m | 1.2 | 1.6 | 2 | |||

| Drying length | m | 8 | 10 | 8 | 10 | 8 | 10 |

| Material distribution thickness | mm | 10~50 | |||||

| Operating temperature | ºC | 50~120 | |||||

| Steam pressure | mPa | 0.2-0.5 | |||||

| Water evaporation | kg/h | 120~300 | 160~400 | 150~375 | 190~475 | 200~500 | 240~600 |

| Steam consumption | ≤2kg steam /evaporation 1Kg water(for vegetable&Chinese herbal medicine) | ||||||

| Total power | kw | 27 | 27 | 40.5 | 40.5 | 40.5 | 49 |

| Dimension(l×w×h) | m | 11×1.6×3.5 | 12.5×1.6×3.5 | 11×2.0×3.5 | 12.5×2.0×3.5 | 11×2.4×3.5 | 12.5×2.4×3.5 |

| Weight | kg | 4800 | 5780 | 5400 | 6550 | 6350 | 7800 |

Table3. Basic parameters of DW series five-layer dryer

| Model | Unit | DW-5-1.2-8 | DW-5-1.2-10 | DW-5-1.6-8 | DW-5-1.6-10 | DW-5-2-8 | DW-5-2-10 |

| Mesh width | m | 1.2 | 1.6 | 2 | |||

| Drying section length | m | 8 | 10 | 8 | 10 | 8 | 10 |

| Material distribution thickness | mm | 10~50 | |||||

| Operating temperature | ºC | 50~120 | |||||

| Steam pressure | mPa | 0.2~0.5 | |||||

| Water evaporation | kg/h | 100~250 | 120~350 | 110~320 | 140~400 | 150~450 | 200~550 |

| Steam consumption | ≤2Kg steam/evaporation 1kg water(for vegetable&Chinese herbal medicine) | ||||||

| Total power | kw | 21.2 | 21.2 | 21.2 | 22.7 | 22.7 | 22.7 |

| Dimension(l×b×h) | m | 11×1.6×2.7 | 12.5×1.6×2.7 | 11×2.0×2.7 | 12.5×2.0×2.7 | 11×2.4×2.7 | 12.5×2.4×2.7 |

| Weight | kg | 3800 | 4780 | 4400 | 5550 | 5350 | 6800 |

Table4. Basic parameters of DW series three-layer dryer

| Model | Unit | DW3-1.2-8 | DW3-1.2-10 | DW3-1.6-8 | DW3-1.6-10 | DW3-2-8 | DW3-2-10 |

| Mesh width | m | 1.2 | 1.6 | 2 | |||

| Drying section length | m | 8 | 10 | 8 | 10 | 8 | 10 |

| Material distribution thickness | mm | 10~50 | |||||

| Operating temperature | ºC | 50~120 | |||||

| Steam pressure | mPa | 0.2~0.5 | |||||

| Water evaporation | kg/h | 80~220 | 100~320 | 90~300 | 120~380 | 130~400 | 180~500 |

| Steam consumption | ≤2kg steam/evaporation 1kg water(for vegetable&Chinese herbal medicine) | ||||||

| Total power | kw | 21.2 | 21.2 | 21.2 | 22.7 | 22.7 | 22.7 |

| Dimension(l×b×h) | m | 11×1.6×2 | 12.5×1.6×2 | 11×2.0×2 | 12.5×2.0×2 | 11×2.4×2 | 12.5×2.4×2 |

| Weight kg | kg | 3000 | 4000 | 4400 | 4550 | 4300 | 6000 |