Ø The raw material:

Energy Saving Puffed snacks processing line Pillow shapes Spindly shapes core filling snacks making equipment machine can use rice flour,corn flour,wheat flour,other grain flour as material or their ingredient

Ø The processing:

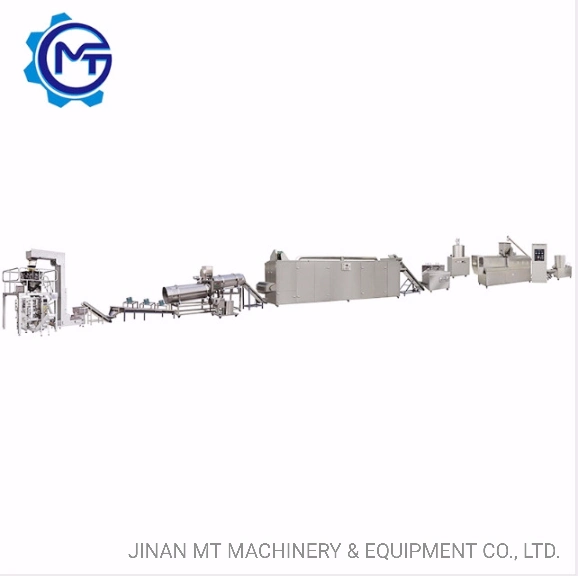

Step: Flour mixing-conveyor-extruding- roasting- Flavoring - cooling - packing - End-products

Description: Mixing the corn flour or&and rice flour,or ingredient with about 15-20% water in the mixer, then transporting the mixed material into the feeder hopper by spiral conveyor, after the extruder can cooking the material and cutting into the shapes at outlet of extruder, the snack then is transported by air conveyor to the continuous roster to reduce the water percentage and roaster the snack more crispy,after roasting, after cooling,the snack can be packed and printed date.

Voltage of Energy Saving Puffed snacks processing line Pillow shapes Spindly shapes core filling snacks making equipment machine

Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

Product Description of Energy Saving Puffed snacks processing line Pillow shapes Spindly shapes core filling snacks making equipment machine

we use corn powder as the raw material to produce the corn flakes (breakfast cereal ),now the corm flakes is very popular all of the world ,it is convenience and nutrition .

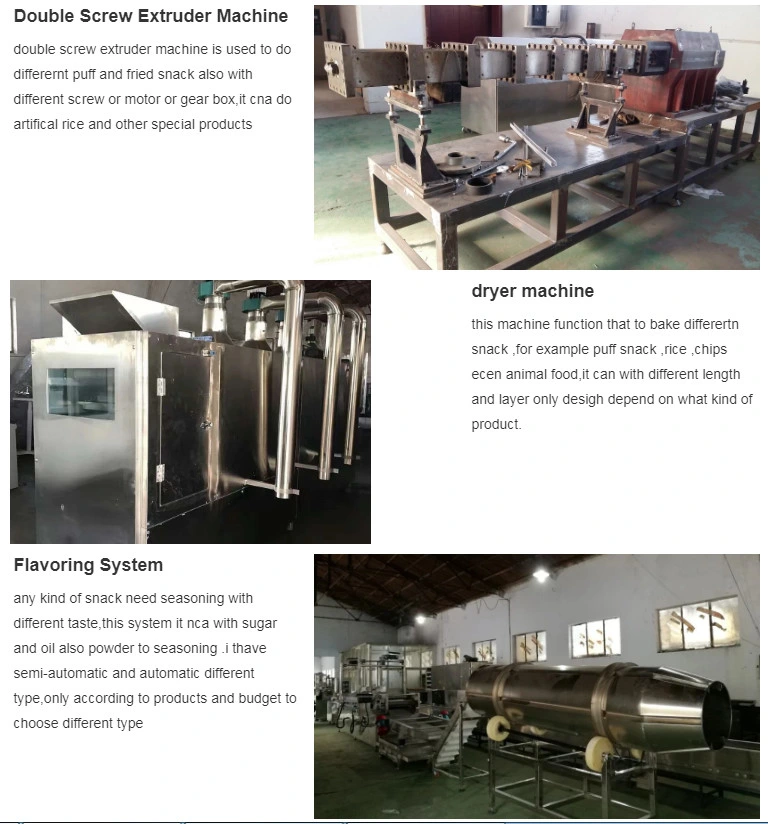

Detailed Images

Technical Parameter

| Model | Installed Power | Real Power | OutPut | Dimension |

| MT65 | 70kw | 40kw | 100-150kg/h | 20000*1200*2200mm |

| MT70 | 100kw | 70kw | 200-240kg/h | 25000*1500*2200mm |

| MT85 | 200kw | 150kw | 300-400kg/h | 30000*3500*4300mm |

The production process flow of Energy Saving Puffed snacks processing line Pillow shapes Spindly shapes core filling snacks making equipment machine

Mix---Screw conveyor---Double-screw extruder----Conver cutting shaper---

Automatic fryer--Automatic flavoring line

Packaging & Shipping of Energy Saving Puffed snacks processing line Pillow shapes Spindly shapes core filling snacks making equipment machine

use wooden box for packing and shipping

Our Certifications

Our Company

MT Machinery Co., Ltd.'s products include double screw, single-screw extrusion machine, automatic continuous frying pot,snack foods, pet food production line production line,bugles crescent fish salad production line, nutrition Rice noodles, fried noodles production line production line,spiral shell production line, the dog biting rubber-production line, breakfast cereals, maize production line,tissue protein production line, regenerated rice production equipment, small instant noodles production line. With the industry's senior talent and technology advantages of the elite, and the "pragmatic, innovative, enterprising, honest"business philosophy, "serious, active, rigorous, efficient"style of doing things, to provide high-quality products to customers.Company with strong technical strength, high-quality products, reasonable price, perfect after sale-service, is willing to sincerely cooperate with you, create a better future.

About installation and after-sale service system:

1. We can provide factory layout according to customer's factory size in advance.

2. When we received your deposit of this order, we will ask our engineers to prepare to apply the visa, when the Core Filling Snacks Puffed snacks Product Machine arrived your country, and we will send two engineers to go and help you to install the Core Filling Snacks Puffed snacks Product Machine, teach your worker(three to four workers) how to operate the Core Filling Snacks Puffed snacks Product Machine, until your worker know the fried snack food line well.

3. Our engineers has responsibility to teach your worker how to clean the extruder, how to change the screw, how to change barrel etc. and we have responsibility to provide technology support with you forever.

4. Our engineers can provide basic formula for producing the fried snack food and help customer to produce good quality food according customer's detailed formula.

5. We provide the spare parts will at preferential price for an extended long time.

6. other item:

a). Free consultation service before, during, and after sales;

b). Free project planning and design services;

c). Free debugging of equipment until everything is functional;

d). Free management of equipments' long distance shipping;

e). Free training of equipment maintenance and operating personally;

f ). Free new production techniques and formulas;

g). Provide 1 year complete warrantee and life-time maintenance service;

FAQ:

Q:Are you a trade company or a manufacturer?

A:We are a manufacturer,welcome to visit our factory and feel machine quality.

Q:How long is your machine guarantee?

A:One year(Calculated from the equipment arrives the customer's side.).We always have new technology support on machine service life period.And welcome to contact us when machine have any problem.

Q:Will you send engineers to install production line in customer plant?

A:Yes,but installation will have extra cost payable by the customer,or you can get local contractors to do the commissioning and send one supervising engineer.

Q:Will you support each food formula?

A:Yes,we support each product production technology and recipe to customer.

All inquiries are welcome.

You Can Send your Inquiry Details in the Below, Click "Send" Now!