Small scale production electronic weigher tea granule packaging machine

Introduction of Automatic electronic weighing scale rice packing machine:

Automatic packaging machine is a kind of automatic packaging equipment, which is upgraded on the basis of particle packing machine. It can automatically complete all the work such as the measurement, bag-making, filling, sealing, printing batch, cutting and counting and so on, automatically complete the packing of the fine particle-like substance. The electrical-sensor detects the color marks on the packing film to keep a perfect picture on each bag.

Advantages of Automatic electronic weighing scale rice packing machine:

1. Key switches plus digital display, reliable operation.

2. Computer-controlled process which makes high precision bags.

3. Automatic tracking color, eliminating false color smartly.

4. Sealing dual temperature control, intelligent temperature control.

Application of Automatic electronic weighing scale rice packing machine:

1. Granular materials: pill drugs, sugar, coffee , grains, tea, salt, desiccant, seeds and other fine particulate, etc.

2. Fluid and semi-fluid products: juice, honey, jam, ketchup, shampoo, liquid pesticide, etc.

3. Powder products: milk powder, soy flour, spices, wet table pesticide powder, etc.

4. Pieces and capsules : tablets, capsules, etc.

5. Packaging materials: paper / PE, Pt / PE, PET / Plated Al / PE, PET / PE, BOPP film, tea filter paper composite packaging materials can be heat sealed.

Applicable products:

Quantitative weighing of tea, seed, monosodium glutamate, feed, sesame and other daily food, condiment and other particles and strip and block materials.

Performance features:

1. High precision digital weighing sensor

2. It can reduce the damage degree of tea by vibrating and circling.

3. easy to operate

4. The weighing system works independently so that it can control the start and stop or change the packaging materials at will.

5. According to the user's requirements, different materials can be assembled and assembled to expand the application scope.

6. Strong compatibility, which makes it easy to use with other packaging equipment.

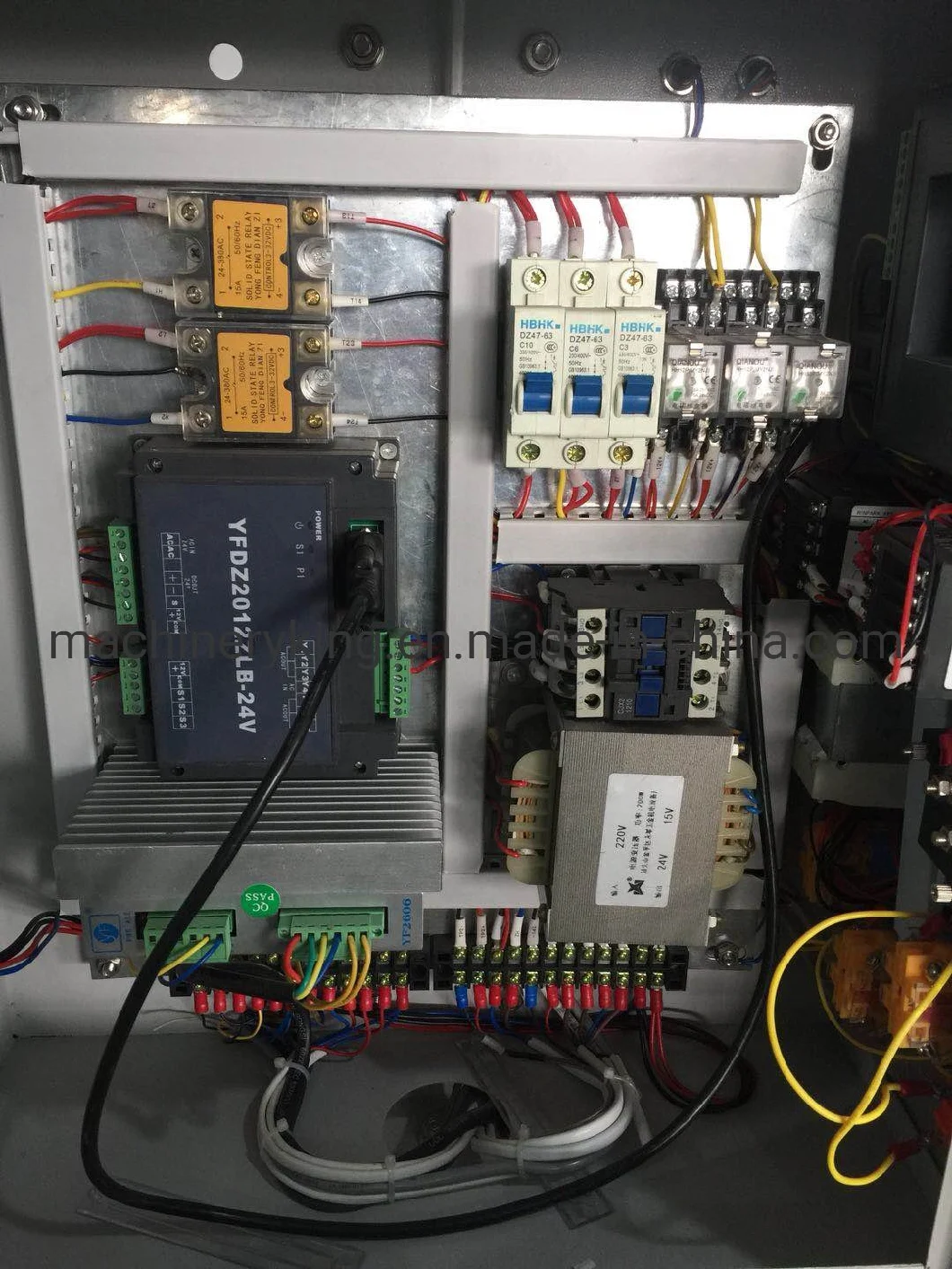

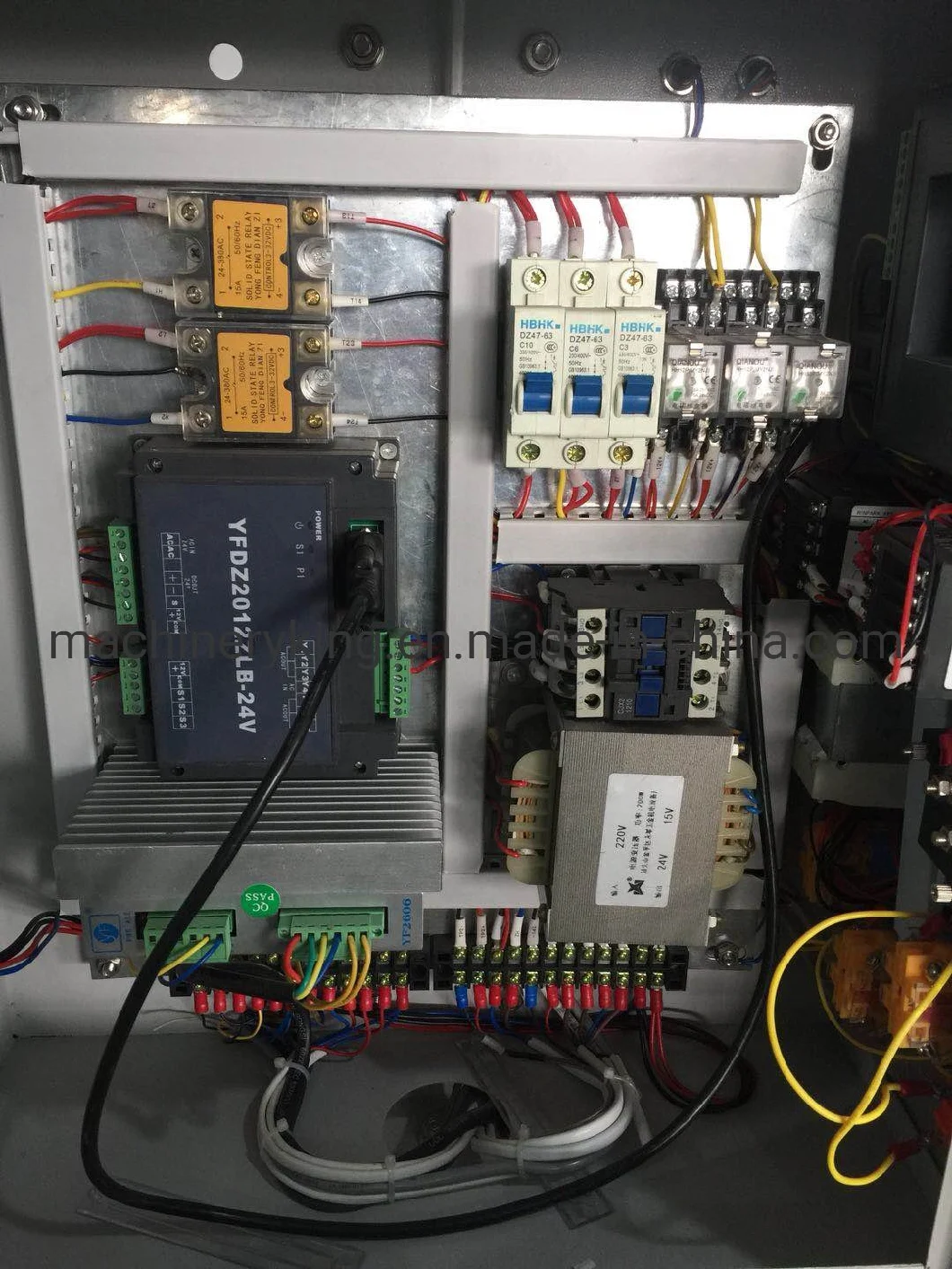

The principle & construction of the machine:

The main construction of the automatic filling machine is the electric vibrator feeder and weighing hopper. The upper part is the reserve hopper,

the raw material(such as sugar) is loading into the reserve hopper by the elevator conveyor. Beneath the reserve hopper is the vibrator feeder's tray, the sugar falling on the tray at the effective of gravity. The machine's intelligent will control the vibrator working and vibrating, the tray will forced vibrate, this will make the sugar that accumulated on the tray vibrates and flow into weighing hopper. The weighing hopper is fixed with weighing sensor(load cell) and the loaded sugar weight is monitored continuously. There will comes an electric signal from intelligent control system that shut off the vibrator feeding at the point of loaded weight sugar reach to target weight value(for example user want filling 1000g sugar per pouch, the 1000g is referred to target weight value). The next is user control the approach switch this will comes another electric signal to initiate the small motor and split and open the weigher hopper's jaw, the sugar will falling and discharge into pouch/bag.

Packaging details:

1. The machine is PE film winding to protect machine off corrosived and rust;

2. The machine is well wire tighted to protect machine off damage in shipping container;

3. Export standard plywood case, composite material, fumigation-free;

4. With easy lifting corn by the forklift.

Warranty and after sale service:

1. Warranty: 24 months. Whole life time technical support service.

(A). During warranty, if any mechanical & electrical componment part malfunction, we offer the spare parts freely, but the DHL/Ocean shipping

Cost is on consumer's bill;

(B). Out of warranty, if any mechanical & electrical componment part malfunction, we offer the spare parts and charge with factory price, but the DHL/Ocean shipping Cost is on consumer's bill;

2. Our engineer's door to door service is available at buyer/user's request, but we will charge the round trip air ticket cost, accomodation cost,

Apply visa cost and another extra 100$/day for each electrician engineer;

3.Within 24 hours on line responding to customer's questions, include but not limited to email, tel & mobile, WhatsApp, Wechat ect.

Introduction of Automatic electronic weighing scale rice packing machine:

Automatic packaging machine is a kind of automatic packaging equipment, which is upgraded on the basis of particle packing machine. It can automatically complete all the work such as the measurement, bag-making, filling, sealing, printing batch, cutting and counting and so on, automatically complete the packing of the fine particle-like substance. The electrical-sensor detects the color marks on the packing film to keep a perfect picture on each bag.

Advantages of Automatic electronic weighing scale rice packing machine:

1. Key switches plus digital display, reliable operation.

2. Computer-controlled process which makes high precision bags.

3. Automatic tracking color, eliminating false color smartly.

4. Sealing dual temperature control, intelligent temperature control.

Application of Automatic electronic weighing scale rice packing machine:

1. Granular materials: pill drugs, sugar, coffee , grains, tea, salt, desiccant, seeds and other fine particulate, etc.

2. Fluid and semi-fluid products: juice, honey, jam, ketchup, shampoo, liquid pesticide, etc.

3. Powder products: milk powder, soy flour, spices, wet table pesticide powder, etc.

4. Pieces and capsules : tablets, capsules, etc.

5. Packaging materials: paper / PE, Pt / PE, PET / Plated Al / PE, PET / PE, BOPP film, tea filter paper composite packaging materials can be heat sealed.

Applicable products:

Quantitative weighing of tea, seed, monosodium glutamate, feed, sesame and other daily food, condiment and other particles and strip and block materials.

Performance features:

1. High precision digital weighing sensor

2. It can reduce the damage degree of tea by vibrating and circling.

3. easy to operate

4. The weighing system works independently so that it can control the start and stop or change the packaging materials at will.

5. According to the user's requirements, different materials can be assembled and assembled to expand the application scope.

6. Strong compatibility, which makes it easy to use with other packaging equipment.

| Model | Description |

| TH-PM-G-5 | 4 head Automatic weighing filling machine 1. Machine filling range: 20-1000gram 2. Power supply: 1.5kw, AC220V 50/60Hz 3. Filling weight error: Less than 0.3% 4. Filling capacity: 25-40bags/min 5. Machine weight: 300Kg 6. Size: 1200*600*1900mm 7. Material: stainless steel 304 8. Main configuration: Four head weigher hopper, 4 electric vibrator, touch screen type control box, PLC unit. |

| TH-BBC- 18 | Stainless Steel Bucket Conveyor 1. Machine material: stainless steel 304 2. Power supply: 0.75Kw, AC220/380V, 50/60Hz 3. Machine total height: 2.35meters effective lifting height: 2.0meters 4. machine weight: 320Kg 5. Hopper size: 80cm*80cm, and 200liters 6. conveying capacity: 2-3t/h |

The main construction of the automatic filling machine is the electric vibrator feeder and weighing hopper. The upper part is the reserve hopper,

the raw material(such as sugar) is loading into the reserve hopper by the elevator conveyor. Beneath the reserve hopper is the vibrator feeder's tray, the sugar falling on the tray at the effective of gravity. The machine's intelligent will control the vibrator working and vibrating, the tray will forced vibrate, this will make the sugar that accumulated on the tray vibrates and flow into weighing hopper. The weighing hopper is fixed with weighing sensor(load cell) and the loaded sugar weight is monitored continuously. There will comes an electric signal from intelligent control system that shut off the vibrator feeding at the point of loaded weight sugar reach to target weight value(for example user want filling 1000g sugar per pouch, the 1000g is referred to target weight value). The next is user control the approach switch this will comes another electric signal to initiate the small motor and split and open the weigher hopper's jaw, the sugar will falling and discharge into pouch/bag.

Packaging details:

1. The machine is PE film winding to protect machine off corrosived and rust;

2. The machine is well wire tighted to protect machine off damage in shipping container;

3. Export standard plywood case, composite material, fumigation-free;

4. With easy lifting corn by the forklift.

Warranty and after sale service:

1. Warranty: 24 months. Whole life time technical support service.

(A). During warranty, if any mechanical & electrical componment part malfunction, we offer the spare parts freely, but the DHL/Ocean shipping

Cost is on consumer's bill;

(B). Out of warranty, if any mechanical & electrical componment part malfunction, we offer the spare parts and charge with factory price, but the DHL/Ocean shipping Cost is on consumer's bill;

2. Our engineer's door to door service is available at buyer/user's request, but we will charge the round trip air ticket cost, accomodation cost,

Apply visa cost and another extra 100$/day for each electrician engineer;

3.Within 24 hours on line responding to customer's questions, include but not limited to email, tel & mobile, WhatsApp, Wechat ect.