1.Description of Doubling machine

The FA706 series high-speed yarn doubling machine (this model is a new product model issued by the China National Textile Association) combines two or three strands of cotton, wool, chemical fiber and blended yarn into one strand for twisting or twisting. Textile equipment.

The high-speed and unique design has won three countries, and with its excellent manufacturing, it has reached the level of international similar products and can replace imported machines.

2.Main technical of Doubling machine

| Item | FA706 | FA706A | FA706A II | FA706A(G) | Remarks |

| specification | |||||

| Number of spindles (ingots) | 88(standard),76,100 88 | 88(Standard)80,96 | |||

| Spindle distance (mm) | 280 | 280(middle pitch 1240) | |||

| Consolidated shares (shares) | 2-4 | ||||

| Anti-stacking method | lectronic intermittent anti-stacking mechanism | ||||

| Winding speed (m/min) | 600,500,416,346mechanical speed regulation. frequency conversion stepless speed regulation (must when necessary) | 200-600frequency conversion stepless speed regulation | |||

| he yarn grooved cylinder | two half-half constant speed type, outer diameter, φ81.2, Length 178mm, stroke 156mm, Domestic metal trough or imported metal trough (extra price) users choose. | ||||

| Broken yarn self-stop mechanism | Magnetic sense self-stop power cut | Photoelectric sensor self-stop | |||

| Metering method | Preset digital display electronic meter | ||||

| Feeding method | Pagoda bobbin feeding, horizontal creel. The maximum diameter of 2 strands is φ220mm. 3-piece bobbin with a maximum diameter of φ200mm | Pagoda bobbin feeding, vertical creel. The maximum diameter of 2 strands is φ220mm. 3-piece bobbin with a maximum diameter of φ200mm | |||

| size and form of the package | into a length of 150mm, Max large diameter φ220mm flat yarn | ||||

| Transmission mode | Each side of the car is driven separately, the main motor power is 2x1.1kw | ||||

| Dimensions | FA706 FA706A | FA706A II | FA706 type, FA706A type FA706A II type FA706A II models except All models have a cleaner with a width of 1750mm Height 2320mm | ||

| Number of spindles | length, width, height | spindles | length, width, height | ||

| 100spindles | 14767 1469 1633 | 96 spindles | 15520 1855 1633 | ||

| 88 spindles | 13087 1469 1633 | 86 spindles | 14280 1855 1633 | ||

| 76spindles | 11407 1469 1633 | 80 spindles | 12940 1855 1633 | ||

| Accessories | Cleaning dust blower set | ||||

| User self-care parts | 1. High-speed cotton spinning and woven wood tube 2, according to the user's double-twisting equipment required bobbin (including winding bobbin and feeding bobbin) accessories ordering determination User has no special requirements only for the relevant parts of the wood pipe | ||||

3, Main features of the machine

First, the fuselage is simple and easy to install and adjust

Second, the yarn speed is up to 600 m / min, which is the ideal high-speed yarn speed recognized at home and abroad.

Third, the yarn breakage self-stop system is a unique combination of mechanical and electronic systems. Among them, the magnetoelectric sensor circuit that causes the action has few links, and therefore, it is faster than any one of the photoelectric type, the capacitive type, the piezoelectric type, and the like, and is resistant to environmental interference, so the yarn end that is wound after the machine is broken Almost no waste, reaching advanced levels.

4. The machine is provided with an electric cutting device. When the electric cutting device cuts the yarn, the yarn shovel lifts the running yarn from the yarn guiding groove and pushes the yarn out of the groove of the groove. In addition, the electric cutting device can hold the unbroken yarn to facilitate the operation.

5. The support part of the ingot has the pressure of the winding bobbin from the small yarn to the large yarn, which varies regularly from large to small, and the change rule can also be adjusted according to the process requirements. It is a powerful guarantee for the improvement of the quality of the package.

Sixth, in order to facilitate management, the machine also sets a preset digital display electronic meter on each spindle. This type of watch is convenient and accurate, and is an essential means of modern management.

7. The tension adjusting device of the machine has the function of convenient tension adjustment, and also has the function of clearing yarn, that is, the slit type clearing sheet (type A is not).

Eight, the yarn path of this machine is short and easy to operate.

Nine, the machine is also equipped with a frequency conversion speed control device, so that the yarn speed can be steplessly regulated within the range of 200 m / min to 600 m / min.

Ten, the user can also choose an air splicer.

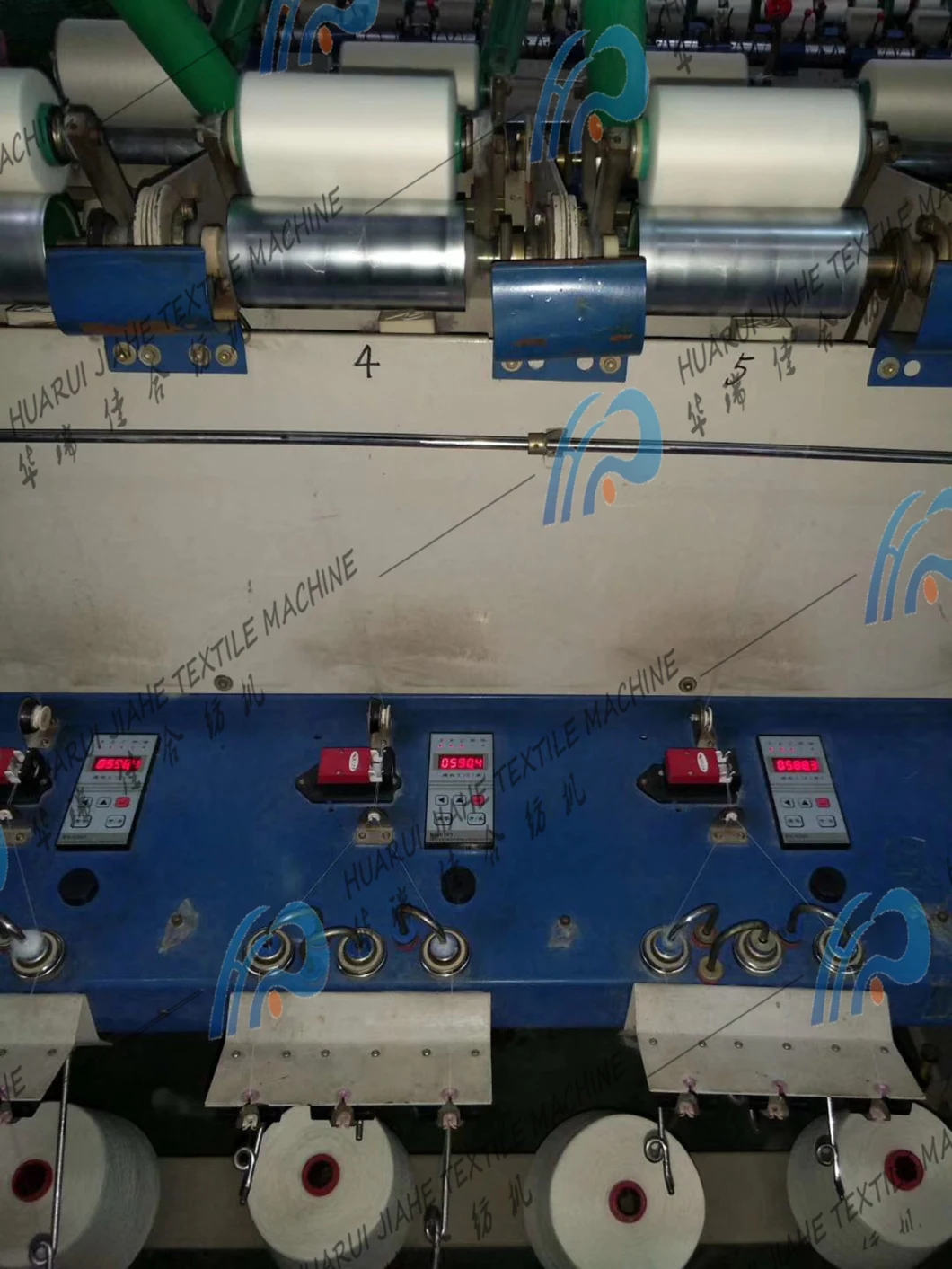

4, Remark: Our company is a professional textile machinery manufacturing enterprises, the main products are non woven machines production line, such as opening machine, carding machine, cross lapper, drying oven and so on, also spinning machines, and we have some customers who want to sell their old machines or want to replace their old machine with new machines, and we will help them to sell these used machine and we will change the main parts and painting again before selling, if you are interested, feel to ask me for more information and specificatons, here are some pictures.

Detail in stock:

132 spindles, Single spindle single control double twisting machine, well-maintained and in production.........